What is MSST20 Treatment?

(Micron Special Surface Treatment version 20)MSST20 is a proprietary surface strengthening technology in which fine particles, selected according to the application, are mixed with a compressible gas and accelerated to high velocity to impact the surface of a metal product.

Effects of MSST20

- Improved wear resistance through enhanced surface hardness

- Enhanced corrosion resistance

- Removal of surface contaminants

- Elimination of microcracks and discharge defects

- Reduced surface friction

- Enhanced plating adhesion

- Improved resin flow and mold-release performance

Comparison Between Shot Peening and MSST20

Shot peening

Φ800㎛- Low heat generation

- Minimal surface modification

- Work hardening effect

- Compressive residual stress is generated inside the material

MSST20

Φ55㎛- Rapid thermal cycling

- Significant surface modification

- Work hardening and microstructure refinement

- Compressive residual stress is generated near the surface

Shot peening is a type of cold working process that typically uses shot balls with diameters of 600–800μm. It is commonly applied to precision parts such as cutting blades but is unsuitable for molds.

MSST20 is a surface treatment that applies rapid thermal cycling to metal components. It uses fine shot balls ranging from 20–100μm in diameter, conforming to JIS R6001 standards (Grade 3 or higher), or equivalent.

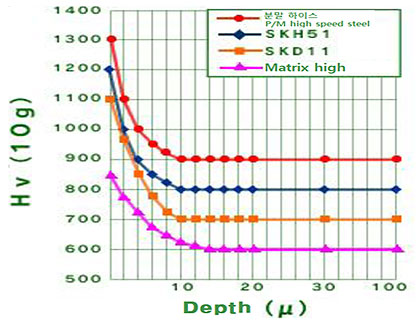

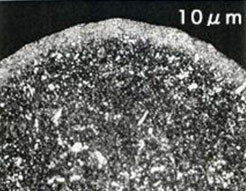

Microstructure Refinement

When MSST20 is applied to XW41 heat-treated materials, it refines the surface microstructure to a depth of approximately 10μm and eliminates microcracks. The surface hardness increases from approximately 700Hv to 1000Hv, and compressive residual stress rises significantly from 200MPa to 1100MPa.

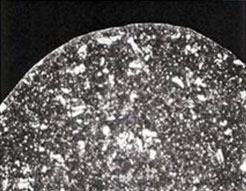

Cross section of material before heat treatment

Cross section of material after MSST20 treatment