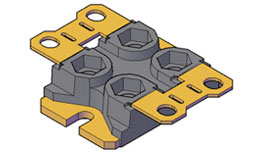

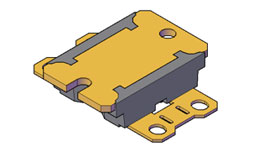

Molding Analysis

Molding analysis is the process of inputting various conditions before mold fabrication to verify product quality after molding. This helps prevent design or manufacturing defects in advance and contributes to shortening lead time.

| Product | SOT-227 | Molding type | 2CHASE 20CAVITY | Press | FUSEI 250 TON (FMTM 250) |

|---|---|---|---|---|---|

| L/F material | CuOF | EMC type | MG15F | Injection Pressure | 400PSI |

| Injection Speed | 21sec | Mold temperature | 175℃ | Clamping force | 150TON |

-

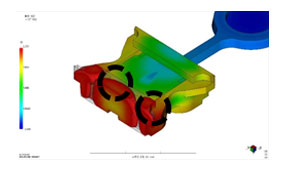

AIR TRAP

Refers to air pockets trapped inside or outside the product. The analysis can trace their location and size, allowing evaluation of potential defects.

-

WELD LINE

A defect that occurs when two or more flow fronts meet. It is analyzed based on the angle between the fronts (acute or obtuse), and its likelihood is visualized using color-coded lines.

-

SHORT SHOT

Occurs due to insufficient EMC flow, typically found in corners, narrow passages, or at the end of the flow path. The defect is identified through flow simulation results.